The future of train travel for commuters

Falling behind schedule due to a delayed train is something many of us have experienced in our lives, with the inconvenience often blamed on line repairs and broken tracks.

Thankfully, due to the efforts of a group of railway experts from the University of Huddersfield, delays could soon be a thing of the past thanks to their latest invention.

Members of the university’s Institute of Railway Research (IRR) are working with engineering giant Siemens to develop an inexpensive and easily-fitted sensor that could turn virtually every rail vehicle into a track monitor.

This would allow each train to easily detect and transmit vital information about the condition of rails and rail bed throughout the network.

Not only could this lead to improvements in safety and reliability, but also major efficiency gains and cost savings for network operators, plus improved ride quality for passengers.

The track monitoring system, named Tracksure, has been developed by Siemens in collaboration with the IRR, as part of the Remote Condition Monitoring Competition supported by the Rail Safety and Standards Board (RSSB) and Network Rail.

Every train in the UK – and a huge proportion overseas – is fitted with a GSM-R cab radio system -Siemens itself produces one of the most widely-used devices. It is now possible to retrofit an inexpensive Tracksure sensor card to the Siemens cab radios and by picking up vibrations they transmit information – received by a control centre – that can detect under-track voids.

These voids are gaps that have developed between sleepers and ballast. In serious cases, they can lead to an increased risk of rail breaks, along with poor vehicle ride performance.

Tracksure would therefore provide early warning of problems – especially at switches and crossings and at the transition to other high value assets such as bridges.

The system has now been described at the recent Railway Condition Monitoring conference in Birmingham organised by the Institution of Engineering and Technology (IET).

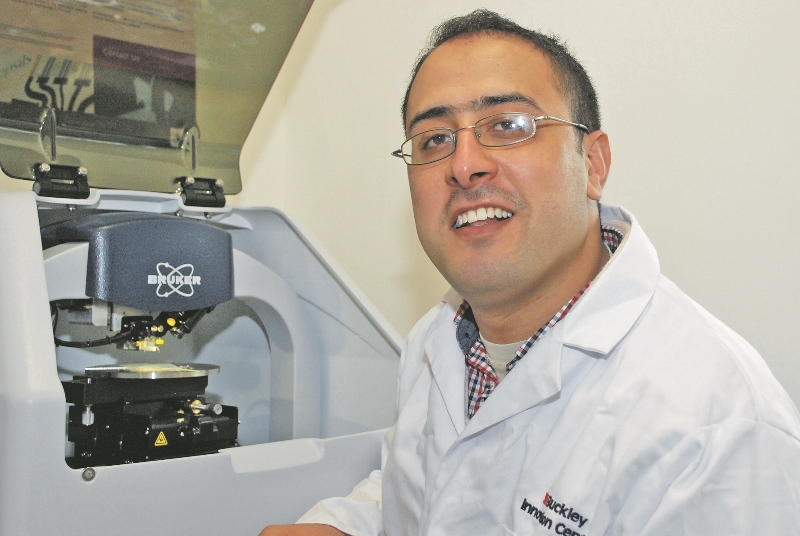

The project was outlined to delegates in a paper drafted and presented by Dr Farouk Balouchi and Dr Adam Bevan of the University of Huddersfield’s IRR, plus Roy Formston of Siemens UK.

The IRR’s role in the project was to develop an all-new algorithm that could be programmed into the Tracksure sensors, so that they detect under-track voids.

“It was very challenging,” said Dr Balouchi. “Initially we used simulation to identify what type of sensors and what accuracy and sensitivity would be needed for the Tracksure prototype. This led on to us developing a highly efficient algorithm which can process large quantities of acceleration data in a short space of time to detect the location and severity of potential track voids.”

At the conference, Roy Formston, of Siemens UK, also detailed how techniques such as machine learning, additional functionality could be included to improve the detection accuracy by making use of multiple train runs over the same section of track.

Now that the practicality of on-board sensors has been demonstrated, the IRR is to collaborate further with Siemens in developing a concept that has the potential to provide levels of ‘big data’ that could provide a huge boost to rail safety and cost-efficiency.